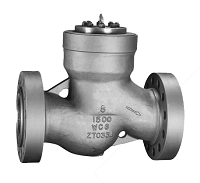

Lift check valve refers to the valve that relies on the flow of the medium itself to automatically open and close the disc to prevent the medium from flowing backward. Check valve is a kind of automatic valve, its main function is to prevent the reverse flow of the medium, prevent the reversal of the pump and the drive motor, and the discharge of the container medium.

Principle Structure:

1. When the medium flows in the specified direction, the valve disc is opened by the force of the medium. When the medium flows backward, the valve disc and the sealing surface of the valve seat are tightly bonded due to the self-weight of the valve disc and the action of the reverse force of the medium on the valve disc, so as to prevent the reverse flow of the medium.

2. The sealing surface of the valve body and disc should be welded with stainless steel.

3. The structural length of check valve is in accordance with ASME B16.10, and the flange connection size is in accordance with ASME B16.5.

Installation and Maintenance:

1. Both ends of the valve passage must be blocked, and there is a dry and ventilated room. If it is stored for a long time, it should be checked frequently for anti-corrosion.

2. The valve should be cleaned before installation, and the defects caused during transportation should be eliminated.

3. When installing, it is necessary to carefully check whether the signs and nameplates on the valve meet the requirements for use.

4. As shown in the figure, the lifting check valve should be installed on the horizontal pipeline.

5. Do not make the check valve bear the weight in the pipeline. The large check valve should be independently supported so that it is not affected by the pressure generated by the pipeline.

6. When installing the check valve, special attention should be paid to the flow direction of the medium, and the normal flow direction of the medium should be consistent with the arrow direction indicated on the valve body.